Creativity Demands OPTIONS

Hot pop or punty style. Fitted base. Through mold. Barn doors. Alignment pins. Specialized venting. Thicker or thinner walls. Left-opening. Clamp dogs. Wood/graphite hybrid.

Neck & Neck

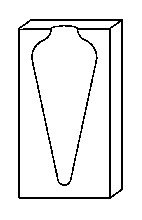

-

This set up assumes the piece will be transferred to the punty and opened to its final shape with jacks. The open end is reduced in the throat for good back pressure. Excellent for stretching lip wraps thin.

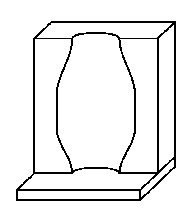

-

This set up is for open ends that need more precision, such as lamp shades with fitters or glassware with a ground lip. It's also good for controlling the thickness of the edge.

The Bases

-

Rounded Bottoms

The bottom of the form is a convex curve, captured in the shape of the mold

-

Flat Bases

The bottom of the form is flat, such as a drinking glass or a vase.

-

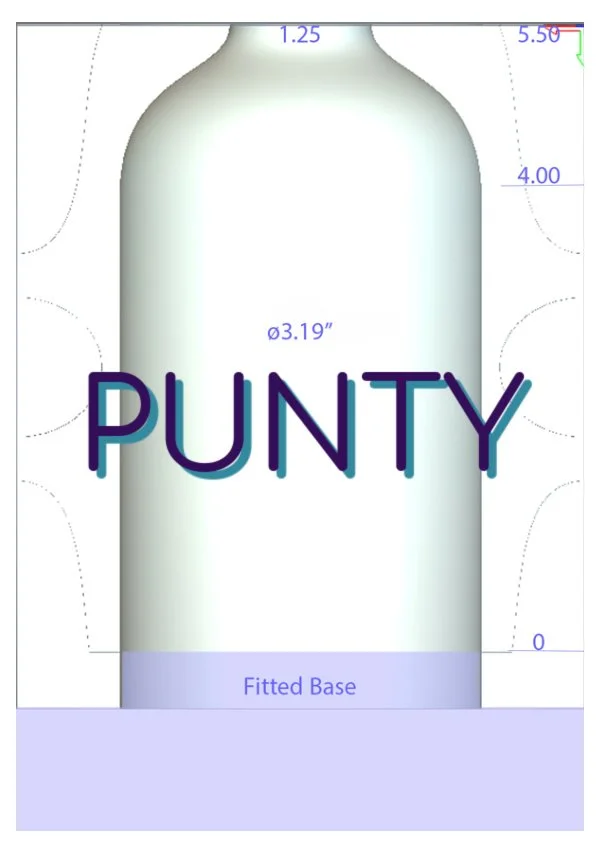

Fitted Bases

The bottom of the form has a concavity, such as the punt of a wine bottle. Care must be taken that the form can be released once blown.

-

Through Molds

Molds go straight through to a board or the floor. Open on both ends and for use with a base board.

-

Gridded Base

The grid gives it venting. Has a grid shape of channels for venting and used with a Through Mold.

-

Barn Doors

For large, wide forms. Allows for lenses and domed chandeliers to be made easily.

Venting

That steam needs somewhere to go. Blockhead’s Design Team works with glassblowers and designers to select just the right pathways. Finding the path and keeping the shape.

Holding It Together

-

Alignment Pins

Nifty little brass fixtures to keep your mold in line. Embrace consistency.

-

Locking Clamp

Holding the mold sides together so you don’t have to. Easy release.

-

Carrying Handles

For relocating large molds around your work space. The grips lock halfway up so as not to crush fingers.